8/14/15:

Hackers wrecked my web site a few monthes ago and I didn't have a backup of my Cobra vs non-Cobra alternetors page, so I tried to recreate it here.

5/12/10:

I found a new, improved coolant crossover tube plug, so I bought a pair, one for my current motor and one for my new motor. Documented here.

11/16/09:

After a little over a year and about 9000 miles, my 2007 Shelby GT500 twin disk clutch started slipping. I decided to buy a McLeod Street Twin setup and a McLeod SFI rated bellhousing. I am documenting this project here.

10/31/09:

I got curious about the effect of no VSS signal on a tune, so I studied a stock 97 Cobra tune. I documented what I found here.

10/11/09:

People have been asking about the fuel pump schematics. I put them here.

9/27/09:

I had to figure out what spark plugs I should be running.

6/16/09:

I have reconstructed the old IMRC Delete Relay Circuit.

5/26/09:

In planning the Teksid Terminator swap, I needed vacuum diagrams for both cars. Since they were so hard to find, I am posting them and other vacuum system information here.

12-3-08 to 4/18/09: 96 Cobra AC Condenser Mod

Since I needed some AC service, I decided I needed to replace the super dense 96 Cobra AC condenser with the much less dense 97 Cobra AC condenser. I documented the project here.

11-12-08: Fuel Pressure Transducer Relocation

About a year ago, my Autometer Phantom fuel pressure gauge started reading about 10 PSI too low, damaged due to vibration. So I had to replace it and relocate it off of the fuel rail.

6-16-08: Fuel Pump and Radiator Upgrade

I had a Mallory 255LPH fuel pump installed today. I also had a Fluidyne radiator installed today as well.

5-10-08: Fuel Pressure Problem

I noticed on the WB that I was going lean up top, so I looked at my fuel pressure gauge and saw that I am not getting over 39 lbs of fuel pressure even when I am at 6 lbs of boost. Since I recently replaced the fuel filters, I suspected the BAP/Fuel pump circuit might be giving me trouble again. So I pulled the trunk liner out and this is what I found at the input wire for the KB BAP where the people who installed it crimped in a butt connector in front of the BAP fuse:

As you can see, it has been getting really hot. This is another example of why crimp connectors are a very bad idea!

I cut out the burned part of the supply wire and put insulated spade lug connectors on both sides of the BAP for diagnostic purposes. This enabled me to bypass the BAP to run the stock fuel pump circuit.

Since the Cobra has a 2 stage fuel pump system, at idle, the fuel pump voltage is about 10.87V. When I rev the engine up to about 4K RPM, that jumps up to about 12.1V. This seems about right, although, I am really not sure. The fuel pump wire stays nice and cool to the touch.

I then hooked up a variable power supply to the KB BAP to test it. With an input voltage of 7.9V, the BAP output varies from 13.04V to 17.28V as the BAP knob is turned from 0-5. With an input voltage of 12.6V, the BAP output varies from 13.04V to 17.28V. With an input voltage of 14.5V, the BAP output varies from 14.3V to 17.28V. My power supply can only supply 3A, so I could not test the BAP using the variable power supply with it hooked up to the fuel pump.

At this point, I put the BAP back into the car's fuel pump system. With the ignition on, but the car not running, I saw 0.126V at the input of the BAP, and 0.033V at the BAP output.

After I started the car, at idle, the input voltage of the BAP was about 7V, and the output about 12.5V regardless of the BAP knob setting. At 4K RPM, the input voltage of the BAP was12.1V and the output is13.0V with the knob at 0, and 15.9V with the knob at 5. The wire is noticeably warm to the touch and I am seeing a 0.2V drop across the inertial cutoff switch.

I have no idea what is going on with my fuel pressure. I have verified that it is running lean up top and changing the MAF transfer function has no effect, so it appears I have a definite fuel delivery problem...

Spark plug wiring diagram and lengths:

I decided to replace the Ford Racing spark plug wires. Just because I am so detail-oriented, I drew a diagram of the plug wire routing. I also measured the old Ford Racing wires and the new ones and recorded both:

Note: For SCT datalogging, the passenger side is Bank 1 and the driver's side is Bank 2. Front O2 sensor is sensor 1 and the rear is 2.

Per Ken at Kenne Bell, here is how you test a Boost-A-Pump:

"There are two sheathed cables - one contains the "activation" circuit wires (vacuum/boost switch), the other is the control cable. Make sure you do not mix these up. Both sheaths contain red and black wires, so you can't tell which is which if you cut these - we label them from here "C" for the Control cable, and "S" for the Switch.

To test it is simple: jumper the S cable wires, and then use the controller to turn the voltage up and down. Check the output lead (large red wire without the Fuse) coming out of the BAP with a DVM probe (positive) and touch the DVM negative to a ground. The voltage should go from approx. 12.5 to 17 as you turn the dial."

I figured out that the car must be running when you run this test.

How to identify a KB 1.5 vs a KB 1.7:

Kenne Bell originally shipped thier supercharger kit for the 96-98 Cobra with a 1.5L blower, but have since switched to a 1.7L blower for that kit.

Per James at KB, the serial number stamped on the side of the blower will have a "3150" in it if it is a 1.5L unit and "417" in it if it is a 1.7L unit.

Initial install of the Kenne Bell supercharger:

On July 18th, they put the car on the dyno to check it and it ran fine for two pulls and then it got very lean for subsequent pulls. Today on July 19th, they learned that the MAF sensor is pegging. Kenne Bell is overnighting an adapter that enables then to use a Lightning MAF sensor which should not peg. Here are pictures of the car on the dyno of the BAP and of the Griggs Racing subframe connectors. And another picture under the hood.

Here are pictures of the install of the Kenne Bell supercharger kit taking place during June and July of 2006.

These high res pictures are of my stock Cobra engine before the installation of the Kenne Bell supercharger. The car including the engine are at about 50K miles in April of 2006.

Install a Volant CAI & analyse it:

I installed and analysed a Volant CAI. Too bad you can't get these anymore.

Bottom line, it looks like the Volant kit gives me an 8-10*F improvement in IATs.

Cheap Mini Oil Catch Can

I wanted to stop the oil loss and gunking up of my intake and IMRCs, so I made my own cheap mini oil catch can.

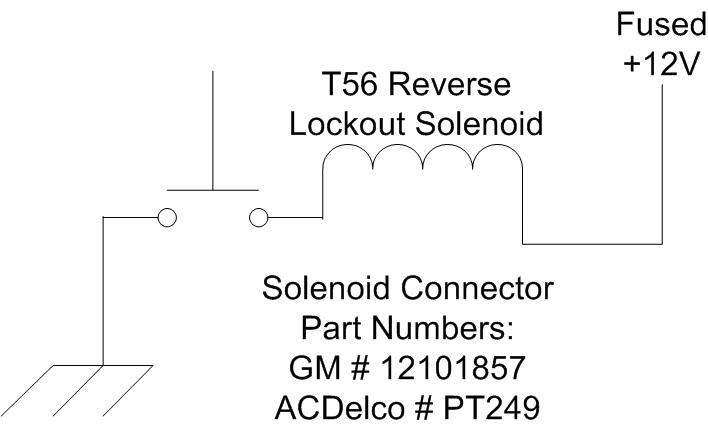

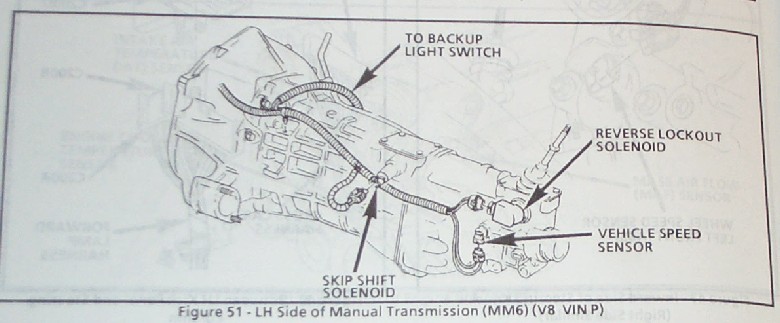

T56 Reverse Lockout Solenoid Connector:

Most people who drop a Tremec T56 6 speed transmission into a Mustang use two hands to muscle through the electric reverse lockout. For those who want to hook up a pushbutton switch to enable the electric reverse lockout release, the part numbers for the solenoid connector of the T56 are either GM # 12101857 or ACDelco # PT249.